Uniforms do more than identify a team; they weave the vibrant threads of identity and professionalism into every fabric.

Sublimation printing is a big deal when it comes to making uniforms. This printing method has many advantages, making it the best choice for making outfits that are not only bright and eye-catching but also very durable against the wear and tear of daily use. This method ensures that the colors stay bright and the details stay clear.

However, which sublimation printer is the best choice? In this article, we delve into the features and performance of top models to help you make an informed decision tailored to your specific printing needs.

Sublimation Printing for Uniforms

In sublimation printing, solid dye is turned into gas by high heat. The gas doesn't go through a liquid stage so that the dye can fuse directly with the fabric. With this new method, the ink is built into the fabric instead of just sitting on top of it.

Benefits of Sublimation Printing for Uniforms:

> Durability: One of the most compelling advantages of sublimation uniform printing is its durability. The color infused into the fabric is impervious to fading, even after multiple washes and extensive exposure to sunlight. This makes it ideal for uniforms that endure frequent laundering and rigorous use.

> Color Vibrancy: Sublimation allows for exceptionally vibrant and dynamic colors. Since the dye bonds at a molecular level, it creates crisp, clear, and long-lasting colors that pop, making it perfect for uniforms that must stand out in a crowd or represent vibrant brand imagery.

> Design Flexibility: This printing method offers unparalleled design flexibility, enabling complex and detailed images to be printed with precision. There are no limits to the palette or gradient of color, and the ability to print edge-to-edge enhances the overall aesthetics of the uniform.

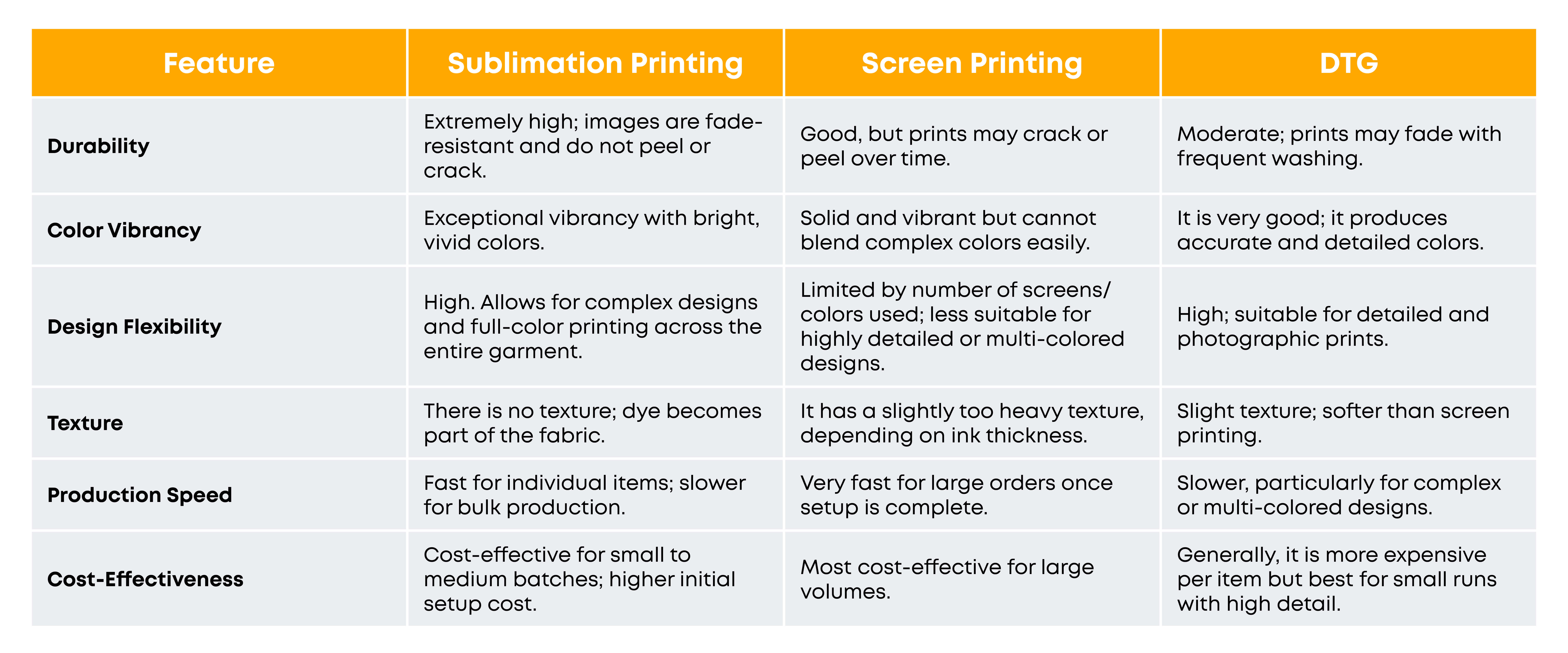

Comparison with Other Printing Techniques

Here's a detailed comparison table illustrating the differences between sublimation printing and other popular printing techniques, such as screen printing and direct-to-garment (DTG) printing:

Key Considerations Before Choosing a Sublimation Printer

Selecting the right sublimation printer for uniform production involves more than just comparing brands and prices; it requires a deep understanding of your specific needs and the capabilities of different printers. Here are some essential considerations to guide your decision:

Determining Your Printing Needs

> Volume: How many items will you need to print at a time? Consider the scale of your operations—whether you're handling large-scale orders for a whole school or sports league or smaller, more customized batches.

> Frequency: Assess how often you will use the printer. High-frequency use demands a robust machine that can handle consistent operation without degradation in quality.

> Variety of Uniforms: The types of uniforms you plan to print (e.g., uniform logo printing, jerseys, jackets) will influence your choice. Different materials and cuts may require specific features from a printer to achieve optimal results.

Differences Between Sublimation Printers

> Consumer Printers: Generally more affordable and compact, these printers are suitable for low-volume, infrequent printing tasks. They are more straightforward to use but may not offer the durability or quality needed for commercial purposes.

> Professional Printers: Designed for high volume and frequent usage, professional sublimation printers offer superior speed, efficiency, and quality. They are a significant investment but are essential for producing commercial-grade products.

Factors to Consider

> Print Quality: High-resolution printing capability is crucial for producing sharp, detailed graphics that enhance the uniform's quality.

> Speed: Depending on your output requirements, the printer's speed can be critical. A faster printer helps maintain productivity, especially under tight deadlines.

> Material Compatibility: Ensure the printer can handle various fabric types and thicknesses, as uniforms often involve materials from polyester blends to stretchable fabrics.

> Ease of Use: Look for features like user-friendly interfaces, easy maintenance, and good manufacturer support to ensure smooth operations. Training staff to use sophisticated equipment can also be a consideration.

By meticulously analyzing these factors, you can choose a sublimation printer that meets your immediate needs and scales with your growth in the dynamic field of team uniform printing.

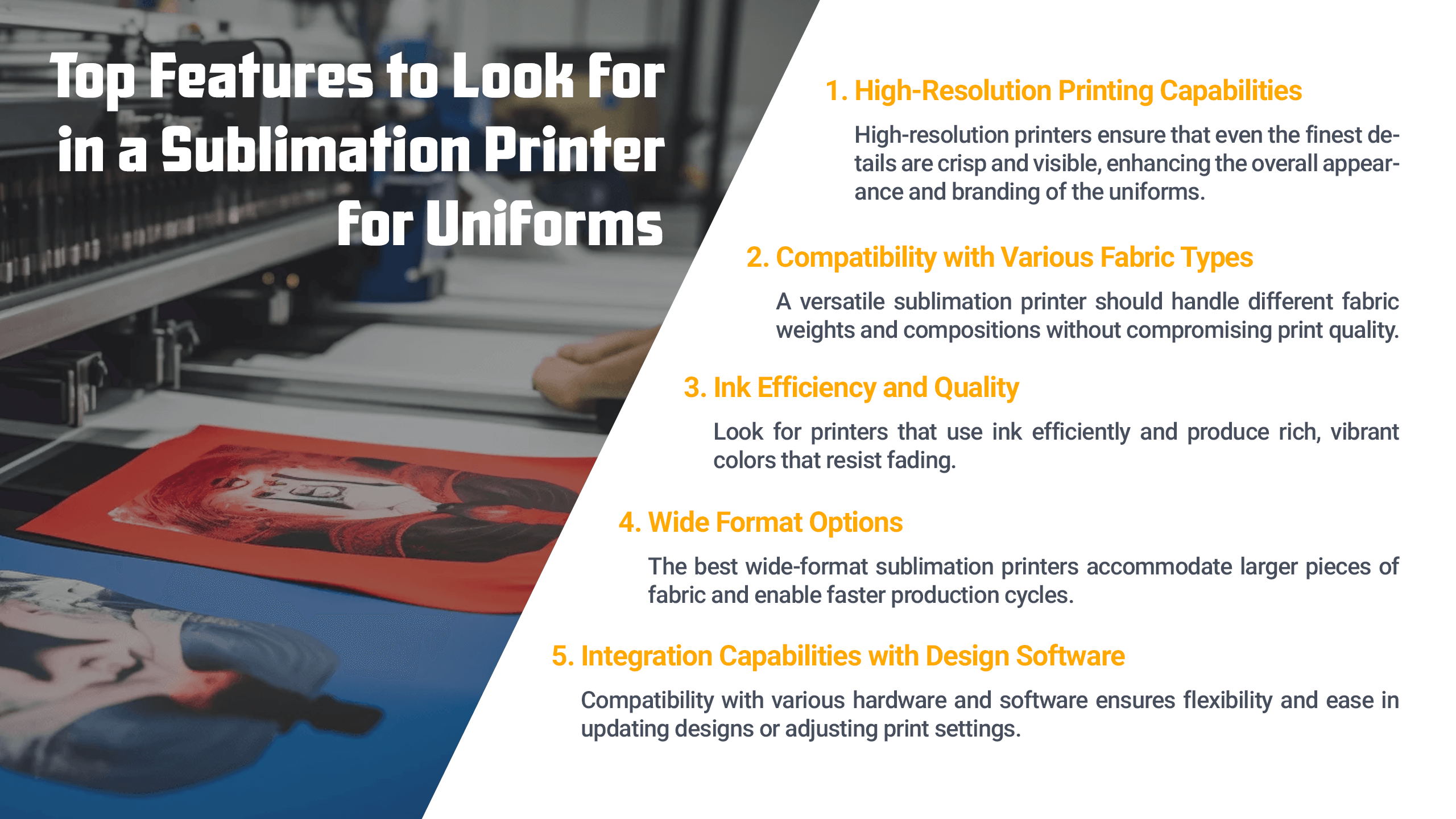

Top Features to Look for in a Sublimation Printer for Uniforms

When exploring options for vibrant, long-lasting prints, many ask, "What is the best printer for sublimation?"—the answer often lies in assessing features like resolution, ink efficiency, and fabric compatibility to match specific project needs.

When purchasing a sublimation printer for creating uniform designs, it is crucial to consider specific features to ensure the end product meets professional printing standards. Here’s a detailed look at the top features you should consider:

> High-Resolution Printing Capabilities: The ability to reproduce detailed logos and intricate designs with clarity and precision is crucial. High-resolution printers ensure that even the finest details are crisp and visible, enhancing the overall appearance and branding of the uniforms.

> Compatibility with Various Fabric Types: Uniforms are made from diverse materials, ranging from thick cotton blends to stretchy synthetics. A versatile sublimation printer should handle different fabric weights and compositions without compromising print quality.

> Ink Efficiency and Quality: Ink costs can increase, especially in high-volume t-shirt uniform printing environments. Look for printers that use ink efficiently and produce rich, vibrant colors that resist fading. The ink's quality also impacts the printed uniform's overall durability, which is essential for items subjected to frequent washing and wear.

> Wide Format Options: A wide-format printer is invaluable for printing larger items like jerseys or uniform pants or for handling bulk orders efficiently. The best wide-format sublimation printers accommodate larger pieces of fabric and enable faster production cycles by printing multiple designs simultaneously. Our large-format printing software optimizes this process, ensuring accurate scaling, vibrant colors, and streamlined production for even the most complex bulk orders.

> Integration Capabilities with Design Software and Hardware: The best printer for sublimation printing hardware integrates with advanced design software, like sock design software, allowing for smooth workflow from design creation to print execution. Compatibility with various hardware and software ensures flexibility and ease in updating designs or adjusting print settings.

These features will help you select a sublimation printer that fits your current needs and adapts to future requirements, ensuring longevity and reliability in uniform production.

The Best Sublimation Printers for Different Uniform Needs

If you're wondering, "What is the best sublimation printer for uniforms?" our guide offers insights into choosing a model that meets your needs for quality and efficiency. Here's a breakdown of the best printers for sublimation and heat transfer tailored to different uniform needs, featuring leading brands like Epson, EcoTank, and Sawgrass.

General Purpose: Epson EcoTank ET-15000

When asking, "Which Epson printer is best for sublimation?" consider models like the Epson EcoTank ET-15000 for its excellent print quality and ink efficiency. This printer stands out for delivering excellent quality, speed, and cost-effectiveness across various uniform types. This model balances high-resolution output with an efficient ink system that reduces running costs, making it ideal for businesses needing versatility without compromising quality.

Best Sublimation Printer for Jerseys: Sawgrass Virtuoso SG500

When it comes to sports uniforms, which often require printing on breathable and stretchable fabrics, the Sawgrass Virtuoso SG500 is the best sublimation printer for jerseys. It is specifically designed to handle the demands of sublimating on polyester-based materials, ensuring that the prints are vibrant and durable enough to withstand intense physical activities and frequent washing.

Sublimation Printer for T-Shirts: Epson SureColor F170

The Epson SureColor F170 is a standout choice for uniform t-shirt printing and business uniforms that often use cotton and blends. This printer is renowned for its sharp detail, color integrity, and robust construction, which promises durability through repeated washing cycles, making it ideal for business apparel.

Best Wide Format and EcoTank Printers: Epson EcoTank Photo ET-8550

The best EcoTank printer for sublimation, particularly valued for its affordability and impressive print capabilities, is the Epson EcoTank Photo ET-8550. It offers wide format capabilities up to 13 inches wide and 19 inches long, perfect for larger uniform pieces. Additionally, its EcoTank technology drastically cuts ink costs and is an eco-friendly option for businesses looking to reduce their environmental impact.

When you need to create expansive and detailed uniform design online, choosing the best sublimation printer for large prints like this one is essential for achieving professional-grade results.

Specialized Picks

> Professional Quality: Sawgrass VJ 628

For those seeking professional-grade quality, the Sawgrass VJ 628 delivers. It is the best Sawgrass sublimation printer for a high-volume, high-detail uniform with logo printing, providing unparalleled precision and color consistency.

> Ease of Use and Setup: Epson EcoTank ET-2760

For smaller operations or those just starting, the best EcoTank printer for sublimation is the Epson EcoTank ET-2760. It combines the affordability and ease of use of EcoTank models with excellent print quality and low maintenance requirements.

> Best Sublimation Printer for Cricut: Sawgrass SG500

The best sublimation printer for Cricut users is the Sawgrass SG500. It is renowned for its compatibility and ease of use, perfect for crafting detailed, high-quality designs.

Practical Tips for Setting Up Your Sublimation Printing Station

Creating an efficient sublimation printing station requires thoughtful planning and organization. Here are some practical tips to ensure your setup is optimal for productivity and quality.

Space Considerations and Setup Tips

> Designate a Specific Area: Choose a clean, well-ventilated space dedicated solely to your printing needs. Adequate ventilation is crucial due to the heat and fumes generated during printing.

> Ergonomic Layout: Arrange your equipment and supplies to minimize the need to stretch or bend frequently. Place your printer, heat press, and other frequently used tools within easy reach to streamline your workflow and reduce fatigue.

> Surface Stability: Ensure your sublimation printer and other equipment are on stable surfaces. Any vibration can affect the printer’s performance and, consequently, the quality of your prints.

These options cater to a wide range of needs, from small businesses crafting bespoke business uniforms to large sports franchises requiring durable and vibrant uniforms for their teams. Each printer has been selected for its ability to meet specific challenges presented by different types of fabrics and design requirements.

Essential Accessories and Supplies

> High-Quality Sublimation Ink and Paper: Invest in the best quality sublimation ink and transfer paper you can afford. This ensures vibrant colors and high transfer efficiency, reducing waste and improving the overall look of your finished products.

> Heat Press: A reliable heat press is essential for transferring designs onto fabric. Consider the size of your typical orders to choose a press that can accommodate your most common projects.

> Protective Gear: Include heat-resistant gloves and protective eyewear, especially when handling hot materials or chemicals.

> Cleaning Supplies: Regular cleaning is crucial. Keep tools like syringes for printhead cleaning and lint-free cloths handy to maintain your equipment.

Maintenance Tips

Regular Cleaning: Adhere to a maintenance schedule for cleaning your printer’s printhead and other components. This prevents ink buildup and clogs, degrading print quality over time.

> Keep the Firmware Updated: Ensure that your printer’s firmware is always up to date. Manufacturers often release updates to improve performance and resolve known issues.

> Monitor Ink Levels: Monitor ink consumption and maintain a good supply of ink cartridges. Keeping ink in the middle of a job can cause delays and affect color consistency.

> Document Your Settings: Record print settings and results for different types of jobs. This will help you achieve consistent quality and troubleshoot issues more efficiently.

By setting up your space thoughtfully and correctly maintaining your equipment, you can enhance the efficiency of your sublimation printing process and ensure that your products always meet high-quality standards.

How to Choose the Right Sublimation Ink and Paper

Selecting the suitable sublimation ink and paper is as crucial as choosing the printer. These consumables directly impact the finished product's vibrancy, durability, and quality. Here’s how to ensure you make the best choice for your printing needs.

Recommendations for High-Quality Sublimation Inks and Papers

> Sublimation Ink: Opt for high-quality inks specifically designed for your printer model. Brands like Sawgrass and Epson offer inks formulated to provide optimum performance and color quality. For instance, Sawgrass's SubliJet inks are well known for their vibrant colors and long-lasting properties, which make them ideal for t-shirt printing & custom uniform printing.

> Sublimation Paper: The paper you choose should have high ink absorption and release capabilities. A top recommendation is the TexPrint® or A-Sub paper brands, engineered to maximize color transfer while reducing waste. These papers ensure the ink transfers efficiently to the fabric, producing sharp and vivid prints.

Tips for Testing and Optimizing Ink and Paper Combinations

> Conduct Test Prints: Before committing to a large print run, always conduct test prints with your chosen ink and paper combination. This allows you to see how the colors manifest on the actual fabric and make adjustments if necessary.

> Adjust Printer Settings: Depending on the ink and paper type, you may need to tweak your printer settings for optimal results. This includes adjusting the temperature and time settings on your heat press and the color output settings on your printer.

> Document Results: Keep a log of the ink and paper combinations you have tried, including the specific settings used and the outcomes achieved. This record will be invaluable when replicating a previous job or troubleshooting printing issues.

> Seek Feedback: Utilize resources such as online forums, user reviews, and recommendations from other printing professionals. Learning from the experiences of others can save you time and help you avoid common pitfalls.

> Regular Evaluation: As your printing needs evolve and new products enter the market, continually evaluate new inks and papers that could enhance your printing capabilities. Stay informed about advancements in sublimation technology to keep your business at the cutting edge.

By carefully selecting and optimizing your sublimation ink and paper, you can significantly enhance the quality of your prints, ensuring that the uniforms you produce are not only visually appealing but also durable and professional.

LiveArt’s Insight: For detailed information, check out our step-by-step guide to sublimation printing on products.

Integrating Sublimation Printing into Your Uniform Production Process

Sublimation printing can streamline operations, enhance product quality, and expand creative possibilities. Here are some illustrative examples of successful integrations.

Workflow Suggestions

> Plan Your Layout: Arrange the sublimation printers, heat presses, and finishing areas to minimize movement and handling. Ideally, the layout should allow materials to flow smoothly from one stage to the next without backtracking.

> Batch Processing: Organize production into batches based on design, color, or material type to maximize efficiency. This reduces the time spent changing out inks or adjusting printer settings and speeds up overall production.

> Quality Checks: Implement regular quality assurance checkpoints throughout the printing process. Early detection of issues like ink smudging or color discrepancies can save significant time and resources.

> Maintenance Schedule: Follow a strict schedule to maintain your sublimation equipment. Regular cleaning and servicing can prevent breakdowns that might disrupt the production flow.

Case Studies of Successful Uniform Printing Operations Using Sublimation Printers

Integrating sublimation printing into your uniform production enhances product quality, boosts operational efficiency, and opens up new business opportunities. These case studies exemplify the transformative impact of sublimation printing on uniform production, catering to diverse needs from sports to corporate environments.

Case Study #1: Sports Team Uniforms

> Overview: A uniform printing company specializing in custom uniforms integrated sublimation printing to offer personalized designs with vibrant colors and durable finishes.

> Process: They set up a dedicated sublimation area within their production facility, which made the transition between digital design and physical production easy.

> Outcome: The ability to quickly produce high-quality, customized uniforms at a competitive cost increased customer satisfaction and led to a significant uptick in sports uniform printing orders.

Case Study #2: Educational Institutions

> Overview: A production company partnered with several schools to provide uniforms and event merchandise using sublimation printing.

> Process: They utilized an integrated workflow that connected design submissions directly to their uniform printing setup, significantly reducing turnaround times.

> Outcome: The schools benefited from the enhanced quality of the prints, which were resistant to fading and wear, essential for uniforms that experienced frequent use and washing.

Case Study #3: Real Experience from LiveArt’s Client

Beast Up Sportswear, a prominent supplier of custom sports uniforms, initially chose sublimation printing to enhance the quality and durability of their products but soon realized that mastering this technique was only the first step towards operational excellence.

Facing a flood of custom design orders and navigating diverse customer demands, they teamed up with LiveArt, experts in personalized product design solutions. This collaboration aimed to streamline order handling and boost efficiency, addressing challenges such as instant design visualization and the need for ready-to-use templates, which had become labor-intensive tasks.

Our tailored solution, featuring a user-friendly interface and customizable design features, was perfectly integrated into Beast Up Sportswear’s existing website, simplifying the customization process for clients and aligning seamlessly with manufacturing processes. This strategic move significantly increased order processing speed and volume, showcasing how vital personalization and efficient digital tools are in enhancing customer satisfaction and operational productivity in the uniform production industry.

LiveArt’s Insight: Read Beast Up Sportswear Case Study

Conclusion

Using sublimation printing to make your own uniforms is a smart move that will pay off in many ways. However, the printer you choose is very important, whether you need one that can print many pages for sports teams or detailed, full-color business costumes.

As you move forward, think about how adding sublimation printing to your production line, not just the printer, could help your business become more successful. With the right settings, sublimation printing can elevate your uniforms, ensuring uniform custom designs last longer and showcase the team's professionalism and spirit.

Explore our services to meet diverse printing needs and discover how you can transform your uniform production process today. Contact us now to learn more and take the first step!

FAQ

> Why choose sublimation printing for uniforms over screen printing or DTG?

Sublimation printing offers several advantages over uniform screen printing and direct-to-garment (DTG) printing, especially for uniforms. It provides exceptional color vibrancy and clarity due to the ink becoming part of the fabric, resulting in greater durability and fade resistance. This method allows for more detailed and complex designs, ideal for uniforms that require crisp logos and vibrant colors that last.

> What printer is best for sublimation?

Choosing the best sublimation printer involves assessing your specific needs, such as the volume of prints, variety of fabrics, size, and frequency of use. Consider printers that handle the required output efficiently and are compatible with your frequently used materials. Also, evaluate features like print speed, resolution, and ease of integration with existing workflows.

> How important is the resolution of a sublimation printer for business uniform printing?

The resolution of a sublimation printer is crucial for uniforms because it affects the clarity and detail of the printed design. High-resolution printing ensures that even small text and intricate logos appear sharp and clear, essential for professional-looking uniforms. A higher-resolution printer is particularly important if your designs involve detailed images or various colors.

> What are the cost considerations when choosing a sublimation printer for uniform printing?

The printer's initial cost and ongoing expenses, such as ink, paper, and maintenance, should be considered. High-end sublimation printers may have a higher upfront cost but often offer greater durability and lower ink consumption per print, leading to long-term savings. Consider the cost-effectiveness of different models by comparing their ink efficiency and the yield of sublimation papers.

> How is sublimation printing technology evolving, and what future advancements can we expect?

Sublimation printing technology is rapidly advancing, with improvements focused on enhancing print quality, speed, and substrate compatibility. Future advancements will likely include higher-resolution printing capabilities and more efficient ink formulations that provide better cost-performance ratios. Innovations might also extend to better environmental sustainability, such as less toxic and more biodegradable inks.

> What is the best Epson printer for sublimation?

The best Epson printer for sublimation is widely regarded as the Epson EcoTank ET-15000. This model stands out for its versatility, efficiency, and ability to produce vibrant, high-quality prints across various substrates, making it a top choice for professionals and enthusiasts.